The cause of the malfunction, when the engine speed does not drop at idle, may be improper operation of the throttle slide, needle valve lodging. Also possible idle control error, cylinder gasket burnout and others. The consequences are increased consumption and rapid wear of the motor.

Car owners should know why the idle speed does not drop on a warmed motor, what can be the consequences, and how to solve the problem.

Description of the problem

The standard situation when, after starting the internal combustion engine, the crankshaft speed gradually drops below 1000 rpm. After this, the driver decides to start driving. But there are situations when the engine speed does not reset and remains at a high level even after warming up. In such circumstances, it is important to understand what can lead to a malfunction, how to carry out diagnostics and eliminate the problem of falling rpm at idle.

Normal or not

After warming up the engine, the rpm should be at a level of 650 to 950 per minute. Such a parameter is relevant when resetting the gas and warming up the internal combustion engine to operating temperature. In the heating mode, the engine can spin up to 1500 or 2000 rpm, and this situation is normal. Gradually, the idle temperature decreases and the rpm drops to 1000 rpm or lower.

The second reason why the crankshaft speed may be higher is the simultaneous switching on of powerful consumers: fan, air conditioner, window heating, etc. In this case, the voltage on the internal combustion engine sags, and the motor receives a command to increase the rpm. As soon as the load drops, the crankshaft speed decreases.

What is fraught with high idle speed

If there is no load, the engine is warm, and the control unit does not lower the rpm, the cause may be some kind of malfunction. It is not recommended to ignore the problem because of a number of consequences:

- An increase in the voracity of the vehicle, which is explained by high idling revolutions.

- Problems with the cooling system. The malfunction can lead to the need to replace the pump, sensor or other elements.

- Detonation in the exhaust system. The reason is incomplete combustion of fuel, because of which part of it flies into the pipe and burns in the catalytic converter. The result can be premature failure of the catalytic converter.

- Excessive strain on the transmission, which has to shift at higher speeds.

- Decrease in overall engine life, etc.

Above are the main consequences of the fact that the engine speed does not fall at idle. The task of the owner is to immediately identify and eliminate the problem.

How to diagnose that the idle speed does not fall

Experts identify a number of characteristic reasons why the crankshaft speed does not fall after reaching operating temperature. To determine the malfunction, it is worth knowing the rules for diagnosing different types of engines: carbureted, diesel and injector. For a better understanding, consider the instructions for each of them.

Carburetor and diesel engines

If the revolutions of the engine, working in tandem with a carburetor or on diesel fuel, do not fall:

- Make sure the accelerator pedal is not jammed in the intermediate position.

- Pay attention to the condition of the choke. If the device is inoperative or hangs open, it causes more air and fuel to enter the combustion chamber and increases engine rpm at idle. Even after warming up, they do not drop.

- Check the idle system adjustment and correct air/fuel mixture ratio.

- Check the integrity of the throttle plate. Incomplete closing of the throttle may cause the engine rpm to hang up, drop. Pay attention to the presence of fouling or the integrity of the device.

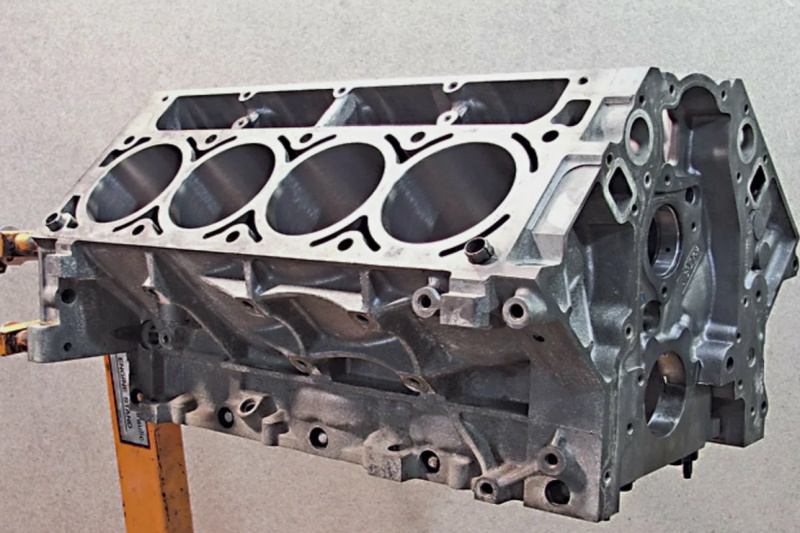

- Inspect the cylinder block gasket. The malfunction is easy to determine without removing the head by indirect signs. One of them – the appearance of oil leakage from the formed gap. An additional sign is the appearance of white smoke from the exhaust pipe. This indicates the penetration of oil into the combustion chamber.

Injector engines

For injector internal combustion engines, there are a number of other reasons why the engine speed does not drop, so the approach for diagnosis changes. In carbureted motors, the problem is usually mechanical in nature.

For power units with an injector, it is important to pay attention to the electronics and controlling elements.

Diagnostics takes place in several stages:

- Check the temperature control sensor. If it is defective, the system will constantly warm up the motor. The result is that the engine speed does not fall even with prolonged idling. The problem leads to overheating of the internal combustion engine, so it is not worth delaying its solution.

- Diagnose the DPDZ. Plays a key role in the operation of the engine with an injector. Collects and transmits data on the position of the throttle flap. If the ECU receives information that it is open, the crankshaft speed increases. Even after warming up, this indicator does not fall.

- Evaluate the condition of the choke return spring. In case of stretching or damage, the spring does not fulfill its functions.

- Pay attention to the throttle cable. If it is defective, the system is not performing its intended function.

- Check the DMRV. Its breakdown can lead to fluctuations in idle speed (rise and fall). As a result, the engine is in the mode of constant heating or, conversely, does not gain the necessary temperature.

For diagnostics, a standard set of tools is required, and to check the sensor – a scanner, laptop and software.

Ways to solve the problem

Increased idle speed is not a reason to immediately go to the service station, because if desired, the problem can be solved with your own hands and in the conditions of the garage. Consider the main faults and steps that help to eliminate them.

Open suction and needle valve lodging

Check the position of the throttle valve. If the part is covered with dirt or has defects, it can not fulfill its duties. To solve the problem, lubricate the cable and the actuator of the mechanism. If the needle bearing is seized, it is recommended to replace it.

Invalid idle adjustment and cylinder head gasket burnout

Errors in idle speed adjustment often occur when cleaning or repairing the carburetor. If such work has recently been carried out, it is worth adjusting the air and fuel supply, and then check whether the engine idle speed drops after heating or not.

If the cylinder block gasket burns out, the only way out is replacement.

Incorrect operation or failure of the coolant temperature control sensor

In case of breakdown of the coolant temperature control sensor it is worthwhile to carry out diagnostics with the help of a special scanner. If the sensor works incorrectly, it needs to be replaced. It makes no sense to repair the device. It is also impossible to leave it in place because of the risk of engine overheating.

Failure of the sensor of mass fuel consumption (DMRV)

To determine the malfunction, an automobile scanner is used. If it indicates a breakdown, the only solution is replacement. Beforehand, check the continuity of the circuit with a multimeter to exclude the possibility of a break.

Throttle position sensor malfunction

The reason that the engine speed does not drop at idle can be jamming or breakage of the throttle position sensor. The solution in such a case is only one – replacement of the part.

To check, remove the block, start the engine and measure the supply voltage. It should be 5 V. After that, turn off the unit and measure the resistance. The optimal level is 0.8-1.2 kOhm, and after closing the flap – from 2.3 to 2.7 kOhm.

Mechanical damage to the throttle spring and cable, nozzle gaskets

If mechanical failure is detected with the spring, cable or gasket, do the following:

- Replace the spring or replace it if it has popped off. Remember that the part is not adjustable if stretched.

- Lubricate or replace the throttle cable.

- Replace the injector gasket or part in the troubleshooting kit.

Other causes and their solutions

In automotive practice, there are other reasons why engine rpm does not drop at idle after heating:

- stuck accelerator pedal – check its position and put it back in place;

- violation of the cable tension – adjust the parameter with plastic brackets;

- air suction – check manifold, gasket, nozzles, nozzle seals for integrity and replace them (if necessary);

- electronic control unit – reset errors or replace software;

- dirty air filter – change it according to the manufacturer’s recommendations;

- insufficient alternator current – requires repair or replacement;

- clogged injectors due to poor fuel quality – have them cleaned;

- turbocharger wear – replace.

How to avoid the problem

The instruction discussed above allows you to quickly identify the reasons why the idle speed does not drop. To prevent the problem:

- control the condition of the main elements of the engine and cooling system;

- check the mechanical condition of the cables and the gas pedal;

- change consumables in a timely manner, taking into account the manufacturer;

- do ECU tuning in the situation if the problem is in the firmware.

With the problem of falling engine rpm at idle, many car owners face. And the reasons for this can be many. Some of them pose a serious danger, therefore, at the appearance of the first signs of malfunction, it is recommended to immediately go to the service station.

0 Comments