The injector is a small-sized device that is in any modern internal combustion engine. Therefore, fuel injectors are a critical component of the engine, without which it is not able to work. Faulty injectors immediately lead to a drop in power and an increase in fuel consumption, starting a chain reaction of malfunctions with the prospect of expensive repairs. Let’s find out why this happens and how to avoid trouble.

What is an injector

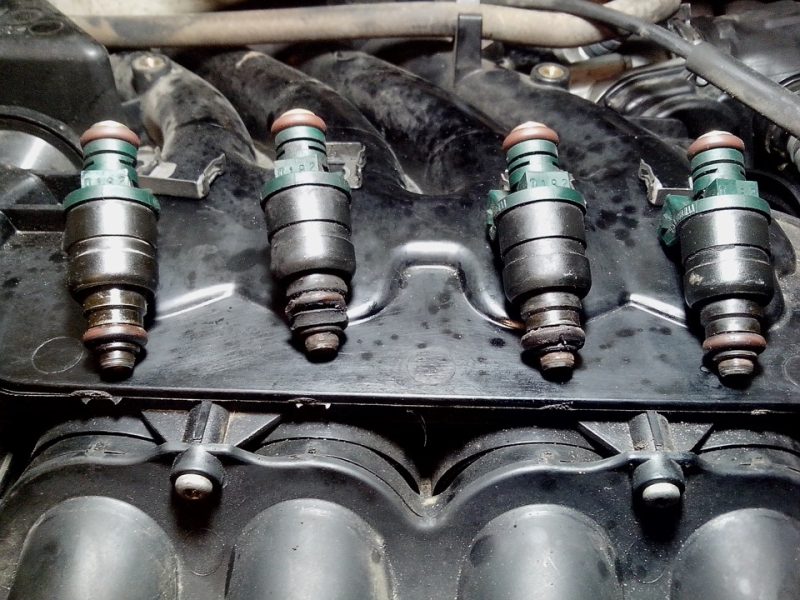

Nozzle, or injector, is the most important element of the injection (injector) power supply system of an internal combustion engine that atomizes gasoline or diesel fuel under pressure into the intake manifold or directly into the engine cylinder. It is the injectors that provide a uniform supply and accurate dosage of fuel, as well as its effective mixing with air. And as a consequence, they have a key influence on the formation of the working mixture, and therefore on the main characteristics of the internal combustion engine.

How many injectors in the engine

This depends on the design and type of motor. For example, at the end of the XX century, car manufacturers used the so-called mono-injection. In such a power system, a single injector, in fact, replaced the carburetor, injecting fuel into the common manifold for all cylinders. However, in modern engines with distributed or direct fuel injection, the number of injectors is usually equal to the number of cylinders. The exception – combined versions, when the fuel in the internal combustion engine can be fed directly into the cylinders and into the intake manifold. With such a complex scheme, the number of injectors is doubled.

How the injectors are arranged

Schematically, any injector consists of a sealed metal housing, a mesh filter, a shut-off needle with a spring and an atomizer. The main design differences of models, as a rule, depend on the working pressure in them. In gasoline engines with distributed injection, it is relatively small, but in modern diesels it reaches 2000-2200 bar. The second important point of the design is the principle of injector control. It can be mechanical, electromagnetic or piezoelectric. Finally, there are pump-nozzles that not only atomize fuel, but also pre-compress it to the required pressure.

Today car manufacturers often use electromagnetic injectors. In this case, the fuel supply is controlled by a solenoid, which at the right moment raises the needle, opening the atomizer nozzles. When the voltage from the windings of the induction coil disappears, the spring pushes the needle down – the injector is locked, and fuel injection stops.

Sometimes the electromagnet is used only to regulate the fuel pressure in a special chamber that helps the needle to open or close the atomizer. Such devices are called electrohydraulic and are usually put on diesels.

How an injector works

The main task of the injector is not just to pour a certain amount of fuel into the cylinders or intake manifold, but to do it at a strictly defined moment in time, in the right amount and under the right pressure, so that the fuel literally turned into an aerosol and effectively mixed with the air. Only in this way the engine will be able to work correctly, giving out the nameplate characteristics.

Therefore, on modern engines, the injectors are controlled by an electronic unit. And the more perfect the power system, the more complex are its program algorithms. Today, it is not uncommon for each injector to make several strictly dosed injections during one cycle. The degree to which the driver presses the accelerator pedal, driving speed, coolant temperature, crankshaft speed – the microprocessor takes into account many factors.

What happens if an injector breaks down

A serviceable injector should have apothecary precision and lightning-fast reaction. And when the factory parameters of the device are violated for any reason, the engine begins to run unevenly, starts with difficulty or smokes.

The first signs of malfunction are not very noticeable to an inexperienced driver, but they are sure to be followed by bigger troubles. After all, fuel supply interruptions directly affect the condition of the ignition, gas distribution and emission control systems. In the most serious cases, a defective injector can wash away the protective oil film from the “mirror” of the cylinder, increasing the risk of scoring and, as a consequence, overhaul or complete replacement of the engine. So it is definitely not worth delaying diagnostics and repair.

Typical faults of injectors

Problems of injectors can be divided into two conventional groups. Less often electronic and electrical components fail. Of course, it is impossible to completely exclude, for example, short-circuiting the coil of the solenoid of the injector, but more often problems arise due to external influences – for example, broken wires or oxidation of contacts in the engine management system.

The second, more common category of potential malfunctions is related to the precise mechanics of the injector. In Russian conditions, it usually suffers not so much from physical wear and tear as from poor-quality fuel. Harmful impurities and additives in fuel often lead to accelerated degradation of seals, clogging, and formation of deposits. Contribute to this and violations in the operation of the car – overheating, untimely replacement of the fuel filter, even prolonged idling can harm the injectors.

As a result, the injector begins to “pour”, that is, to supply gasoline or fuel in excessive doses (and not in time) due to leaky shut-off needle. Or, on the contrary, clogged micro-holes atomizer lose the ability to properly organize the fuel torch. Another option – worn gaskets cease to hold the set pressure in the supply system. And the most dangerous malfunction is when the injector does not close even when the engine is shut off. This threatens the fact that during a long parking in the cylinders fuel flows into the cylinders, which at the next start of the engine causes a hydrostroke and leads to a major overhaul.

Injector Diagnostics

Checking a modern fuel system requires specific skills and experience, as well as caution, especially in the case of diesel engines with high pressure in the supply circuit. Therefore, the average user, as a rule, is left to focus on the consequences of malfunctions. Moreover, it is simply impossible not to notice them: unstable engine operation is usually supplemented by the Check Engine warning light on the dashboard.

Although there are also indirect signs of malfunctions. For example, serious leakage of injectors usually leads to an increase in the oil level in the engine crankcase after parking. The excess fuel flows down the cylinder walls, the lubricant liquefies, and the dipstick begins to emit a characteristic fuel flavor.

In any case, you should not delay a visit to the technical center. It is not excluded that with prompt intervention the matter will turn out to be cleaning of injectors, not their expensive replacement. Plus, these devices rarely fail one at a time, so it is better to prepare in advance for a complete renewal of the set of injectors, especially if your car is not the first freshness, and the mileage is closer to 150-200 thousand kilometers.

Cleaning injectors: flushing and ultrasonic

A significant part of the problems with fuel equipment is associated with contamination of precision channels and holes, which sometimes at the injector is no thicker than a human hair. Therefore, repairmen traditionally recommend cleaning the system components from harmful deposits as the first rescue measure.

Usually offer a choice of two ways: cheaper, without dismantling the injectors from the engine, or more expensive – with the removal of parts and washing on a special bench. In the first case, active additives can be poured directly into the fuel tank, and the second usually uses ultrasound, removing all deposits from the metal. This method is much more effective.

But it is important to realize that such a procedure is not a guarantee of getting rid of problems. It is possible that a faulty or too worn out nozzle will still have to be replaced. In addition, experts do not recommend cleaning for preventive purposes, because aggressive chemical compositions themselves are not too useful for high-precision components. Therefore, before agreeing to flushing, it is necessary to make sure that other systems are in good working order – first of all, ignition. Perhaps the unstable operation of the engine is to blame for substandard plugs or, say, failed sensors.

When you need to change the injector

When the injector does not give factory parameters (they are also checked on special measuring benches), and cleaning does not help. Half-measures in this case are inappropriate: the stronger the wear or contamination of the device, the worse the engine will work, the faster other systems will ask for attention and financial investments. Therefore, it is in the driver’s interest to keep an eye on the condition of the fuel equipment. And at least not to expose it to unnecessary risk by refueling at dubious gas stations.

Totals

- The injector is needed for timely delivery of a strictly defined dose of fuel into the intake manifold or directly into the cylinder.

- Diesel injectors withstand an order of magnitude more pressure compared to parts for gasoline engines. And they cost considerably more.

- The number of injectors usually corresponds to the number of engine cylinders.

- Today, electromagnetic injectors with electronic control are most often used.

- Faulty injectors lead to uneven operation of the motor, reduced power, increased fuel consumption.

- The cause of problems with injectors is often not physical wear and tear, but contamination of the system.

- In this case can help flushing fuel equipment. It is desirable – on a special stand with removal of injectors.

- If after cleaning the injector does not produce the desired parameters, it will have to replace it.

- In the risk zone – old equipment with mileage above 150,000 km: in this case, all the injectors of the engine may need to be updated.

0 Comments